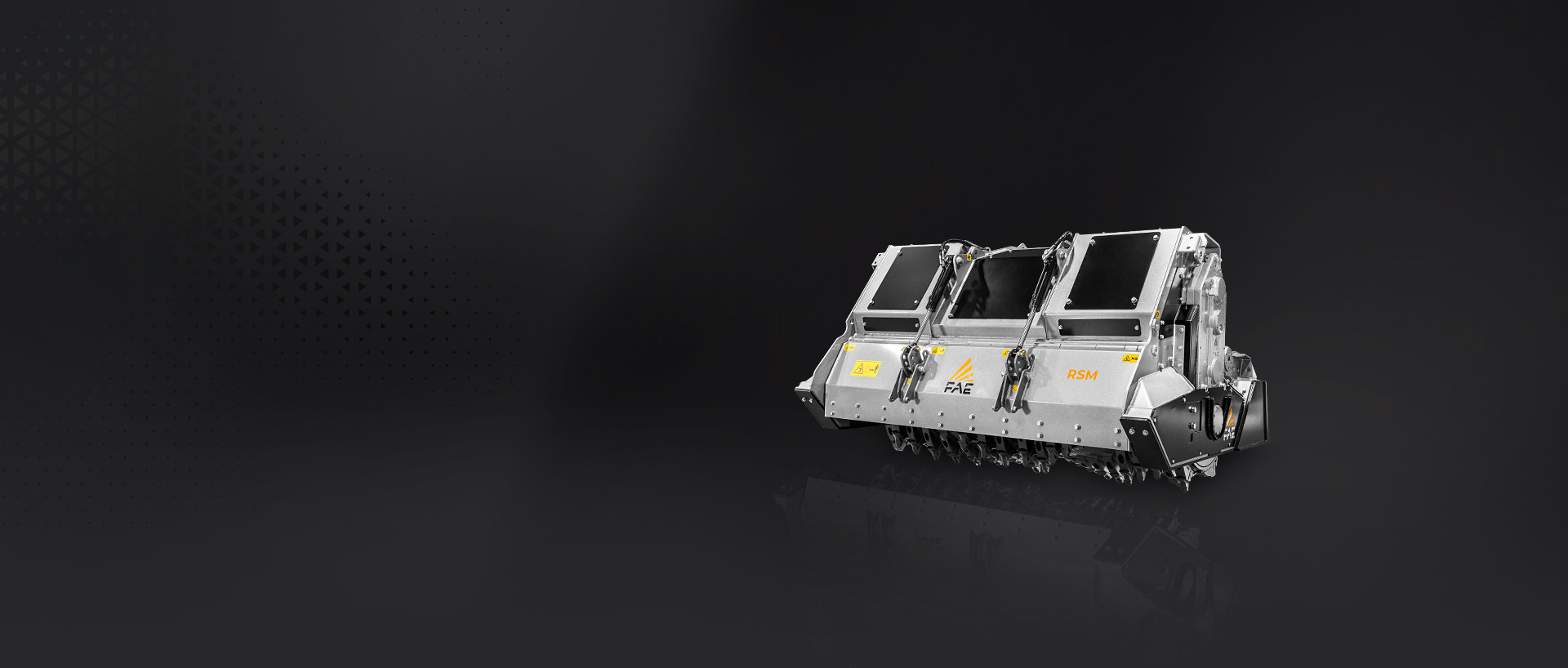

The RSM - RSM/HP models are suitable for crushing slabs of rock and stones of up to 50 cm in diameter and at a depth of up to 40 cm. They are compatible with tractors of between 200 and 360 HP, and have a working width of 230 cm.

The RSM line is recommended for challenging agricultural conversion operations, when the land contains rock and stones of significant dimensions, in order to prepare the field for agricultural use.

The wide opening and the counter blade allow large material to be guided towards the rotor, as well as maintaining consistent performance while working the land. The optional rear grill holds back larger materials, releasing matter only when it has reached its optimum granulometry. The steel dosing blade, available on request, ensures even distribution of the crushed material.

The side reduction gears with an oil-cooling system guarantee efficiency, reliability and reduced maintenance requirements. The gear transmissions guarantee optimum power transfer and, as a result, a longer lifespan for the components.

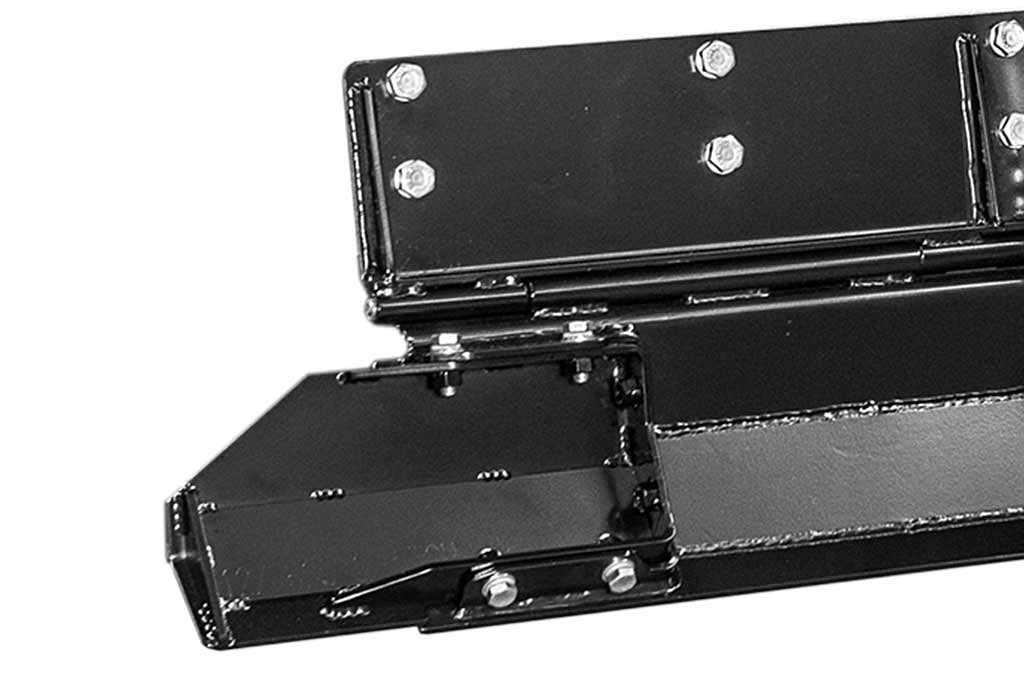

The use of high-resistance, anti-wear steels for the frame, the interchangeable internal and external guards, and the forged-steel tooth-holder with heat treatment all guarantee the RSM a robust construction that has nothing to fear from even the most challenging tasks.

The RSM – RSM/HP stone crusher is available with two types of rotor: type “R” holds teeth with a round tang (“round-shank teeth”) and is ideal for crushing loose stones and rock; while type “G” is ideal for lands where stones emerge. Both rotors come with side teeth which allow the crushing chamber to be kept clean at all times. The offer is completed by 4 different types of teeth, to be chosen based on the nature of the work and the rotor attached.

from 200 to 360 hp

Ø 50 cm max

40 cm max

To efficiently process more material

Maximum strength and durability in heavy duty operations

Greater efficiency and lifespan

Quick and easy maintenance