The MTM enables ground stabilization, milling of slabs of rock, crushing of stones, and milling of asphalt, down to a maximum operating depth of 16 in.

The compact size and excellent maneuverability enable the MTM to work on surfaces which are difficult to reach using self-powered vehicles.

The variable displacement chamber guarantees excellent results in terms of breaking down material.

The volume of the chamber increases based on depth with a reduction in fuel consumption and an increase in operating speed.

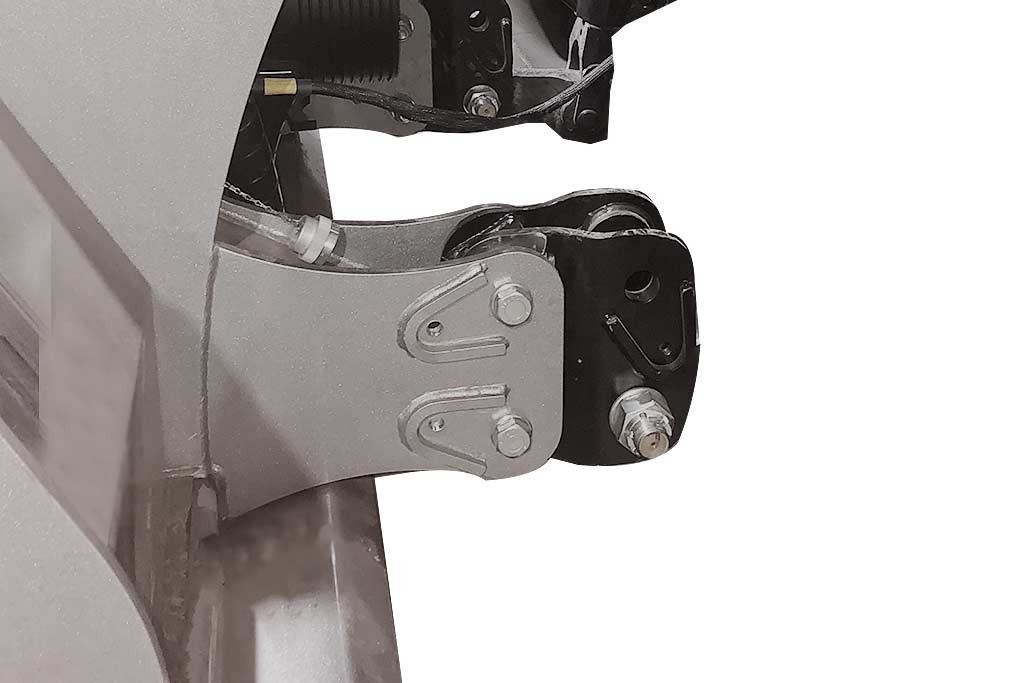

The Hardox wear-resistant counter blade and grid on the rear hood guarantee the desired granulometry of material processed.

from 220 to 360 hp

16 in max

the result is a homogeneously stabilised soil at all working depths

for high productivity and lower fuel consumption