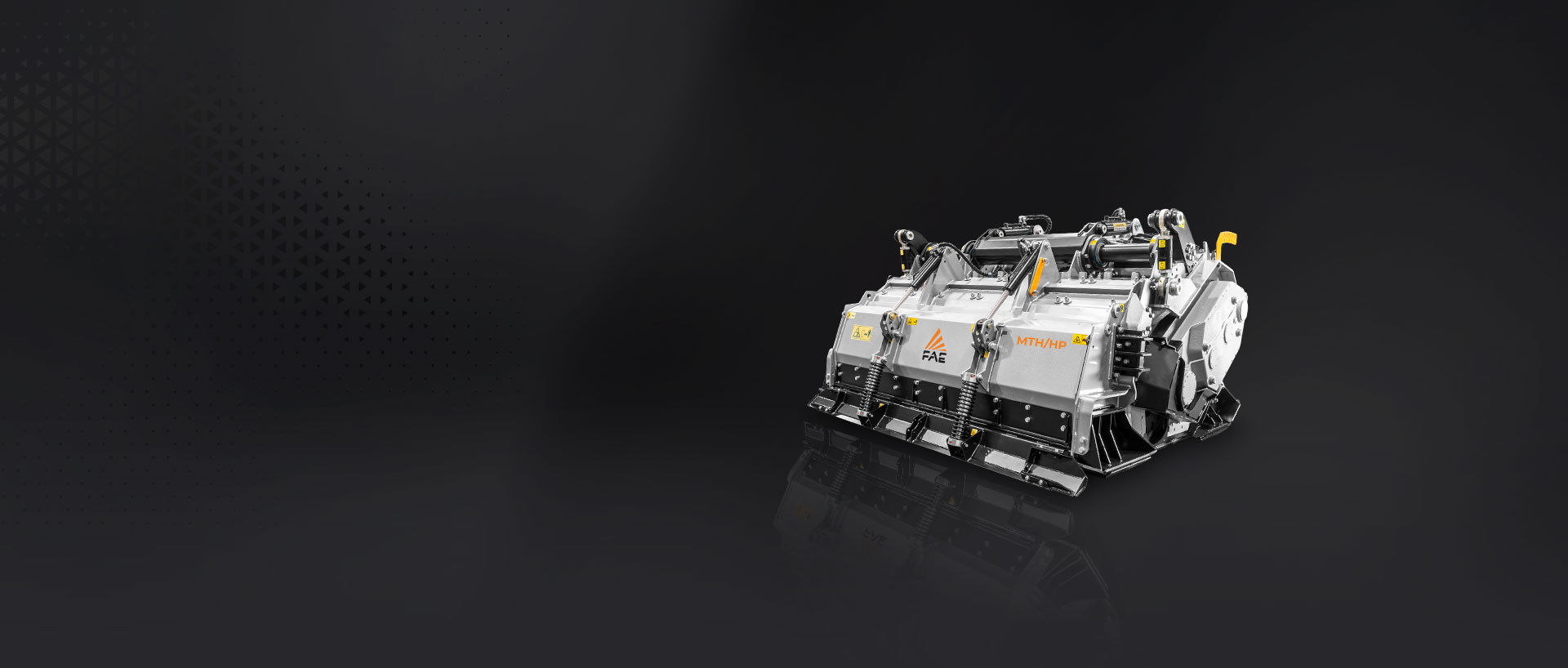

The top-of-the-range FAE multi-function machine enabling milling of rock slabs, crushing of stones, milling of asphalt and ground stabilization, with a maximum operating depth of 50 cm.

The gear transmission enables operation with constantly optimal levels of torque and power.

The variable displacement chamber guarantees excellent results in terms of breaking down material.

The volume of the chamber increases based on depth with a reduction in fuel consumption and an increase in operating speed.

The Hardox® wear-resistant counter blade and grid on the rear hood guarantee the desired granulometry of material processed.

from 300 to 500 hp

50 cm max

the result is a homogeneously stabilised soil at all working depths

To efficiently process more material